TreadWrights Manufacturing Process

Step 1 / Inspection

The first step in our "Remold" process is to inspect our premium recycled casings. The NDT Machine (non-destructive-testing) uses an electrical current to verify the integrity of the steel belts before any tire is moved into the production process.

Step 2 / Buffing

The next step is to remove all of the old tread and side wall rubber from the casing, called “buffing”. The premium casing and belt package isn’t altered from its original state, but simply buffed to the correct texture and measurements to be remolded.

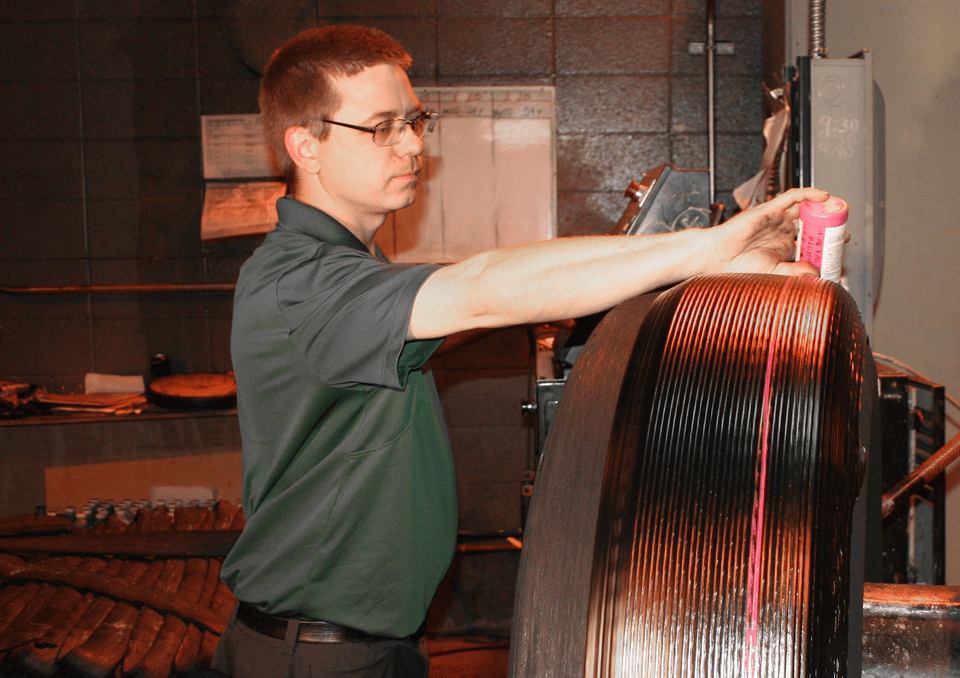

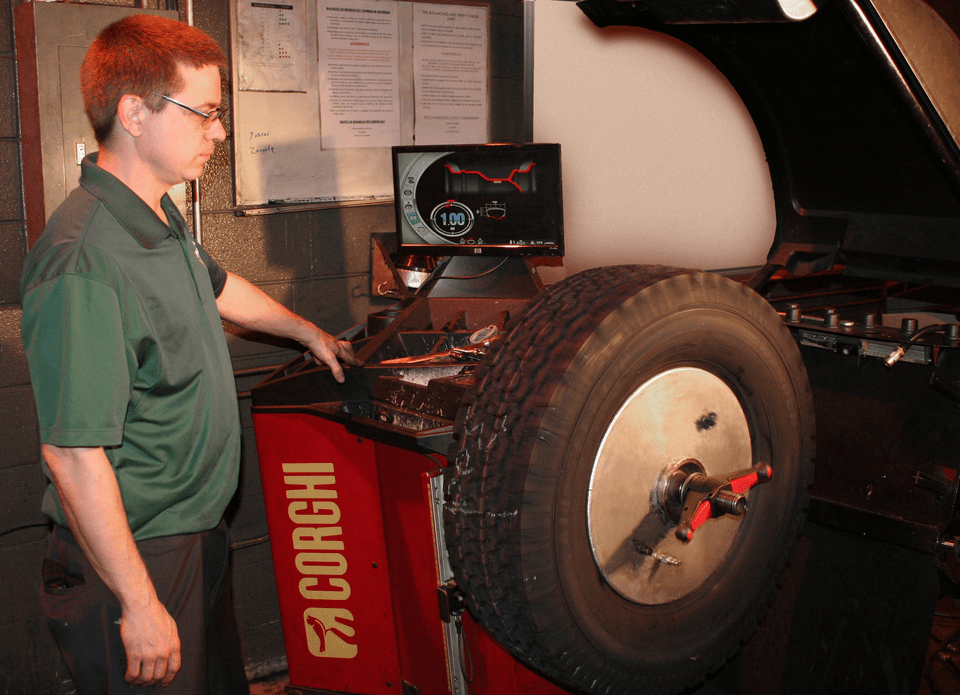

Step 3 / Applying New Rubber

The next step is to apply new mold cure rubber to the buffed casing. The Orbitread machine applies layers of industrial grade rubber compound (higher wear characteristics) to the crown and shoulder of each casing. The sidewalls are given a new layer of sidewall veneer, which brings the entire tire back to a new condition (common in Warden, Guard Dog and Claw brands). All TW tires are balanced with a Corgi Balancer prior to remolding.

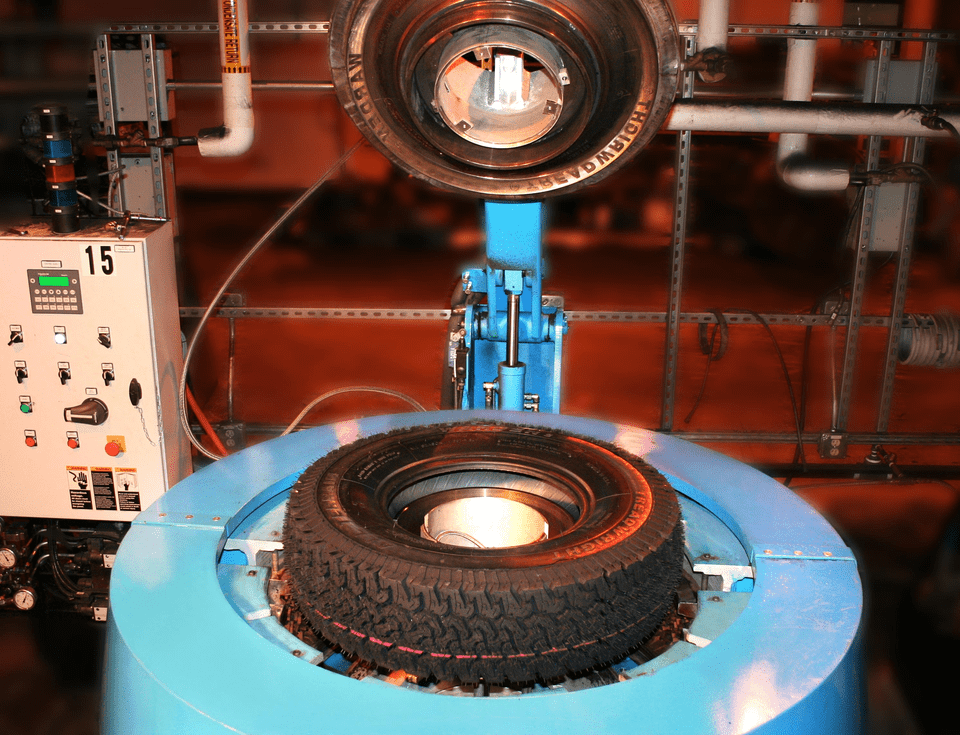

Step 4 / Mold Press

The next step in our manufacturing process is to cure the tire. Each rebuilt casing is individually placed in its corresponding mold/press (size and model) and cured for approximately 60 minutes. The tire is now remanufactured back to a completely new condition. Our presses and molds use the same mold curing process that is standard in all new tire manufacturing plants.

Step 5 - Final Inspection / Final Balancing

The final step is to 100% inspect your new TreadWright tire. We trim all of the excess rubber called "flash" and visually inspective all lugs and branded sidewalls. Tires are then given a second NDT (Non-Distructive Testing) and balance inspection to ensure the integrity and balance specifications of the tire were not changed or altered during the remolding process. We balance all of our tires before shipping to ensure your complete satisfaction!

Take a tour of our shop!

Fox Business came down to run a special on our TreadWright Tires. See how our TreadWright Tires are made.